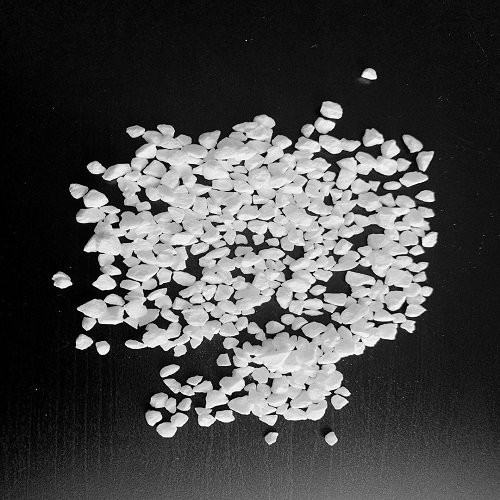

White Fused Alumina

Product Details

Introduced:

White Fused Alumina is made from reduced fusion of high purity alumina powder whose content is Aluminium Oxide(Al₂O₃). It has very high refractory temperature, acid and alkali corrosion resistant, stable in chemical content, high true gravity/density, low porosity rate, thermal shock resistant. It's an excellent corundum aluminium oxide refractory material. White Fused Alumina refractory grades is an important high end material for production of

shaped and unshaped refractory products. Along with Brown Fused Alumina,White Fused Alumina is one of the important refractory material in synthetic corundum family, while with higher Aluminium Oxide content.

White corundum is made from industrial alumina powder, smelted at a high temperature of over 2000 degrees in an electric arc, and then cooled. It is crushed and shaped, iron is removed by magnetic separation, and sieved into a variety of particle sizes. It has a dense texture, high hardness and sharp corners. It is suitable for manufacturing ceramics, resin-bonded abrasive tools, grinding, polishing, sandblasting, precision casting (corundum for precision casting), etc. It can also be used for manufacturing advanced refractory materials. The code "WA" is consistent with international and national standards. Most of them are for export, and there is also a certain amount for domestic users.

Application:

• Alumina Bricks, Alumina Type Refractory Brick Mullite Box Body, Nozzle, Spray Gun, Furnace and Oven Linear

• Unshaped Refractory Materials like Ladle Pouring Material, Drainage Sand, Spraying and Filling Material, Prefabricated Parts

• Refractory Materials in Steel Making, Metallurgical, Cement, Glass, Ceramic, Petrochemical Industries

• Precision Casting and Foundry Sand

Five methods commonly used when white corundum is used as a polishing material:

1、Fluid polishing: fluid polishing relies on high-speed flowing liquid and the white corundum sand particles carried by it to wash the surface of the workpiece to achieve the purpose of polishing.

2、Mechanical polishing: Mechanical polishing refers to a polishing method that obtains a smooth surface by plastically deforming the surface of the cutting material to remove the polished protrusions. Generally, oil stone strips, wool wheels, sandpaper, abrasive belts, nylon wheels, etc. are used. The polishing sheet is operated by hand Mainly, special parts such as the surface of the rotating body can be used with auxiliary tools such as turntables, and ultra-precision polishing can be used for high surface quality requirements.

3、Electrolytic polishing: The basic principle of electrolytic polishing is the same as that of chemical polishing, that is, by selectively dissolving tiny protrusions on the surface of the material to make the surface smooth. Compared with chemical polishing, the effect of cathode reaction can be eliminated, and the effect is better. The electrochemical polishing process is divided into macro leveling and micro leveling.

4、Chemical polishing: Chemical polishing is to make the surface microscopic convex part of the material in the chemical medium dissolve preferentially than the concave part, thereby obtaining a smooth surface. The main advantage of this method is that it does not require complex equipment, can polish workpieces with complex shapes, and can polish many workpieces at the same time, with high efficiency. The core problem of chemical polishing is the preparation of polishing liquid, and the proportion of white corundum sand in the polishing liquid is very important.

5、Magnetic grinding and polishing: Magnetic grinding and polishing uses magnetic green silicon carbide to form white corundum sand under the action of a magnetic field, and the polishing sheet grinds the workpiece. This method has high processing efficiency, good quality, easy control of processing conditions and good working conditions.

Specification:

|

Physical and Chemical Properties |

|||

|

Item |

Value |

Item |

Value |

|

Main Material |

Al₂O₃ |

Color |

White( Blue after calcining) |

|

True Gravity(g /cm³) |

≧3.90 |

Melting point(℃) |

2250 |

|

Bulk Density(g /cm³) |

1.5-2 |

Max using Temperature(℃) |

1900 |

|

Mosh Hardness |

10 |

Linear Expansivity(0-1600℃) |

7-9 |

|

Knoop Hardness(kg/mm²) |

2000-2200 |

Crystal Structure |

Trigonal System |

|

Size Available |

0-1mm, 1-3mm, 3-5mm, 5-8mm, other sizes upon request |

||

Packing bag: Jumbo bag( or according to the customer requirement)

Payment: T/T; D/P; L/C (According to the consultation with the customer)

HS. Code: 2818109000